Every year, millions of Americans fill prescriptions for generic drugs - cheap, effective, and reliable. Or at least, they used to be. Today, you might walk into a pharmacy for a life-saving antibiotic, a blood pressure pill, or an epinephrine auto-injector - and find it out of stock. Not because no one makes it, but because too many companies stopped making it.

The Price of Too Much Competition

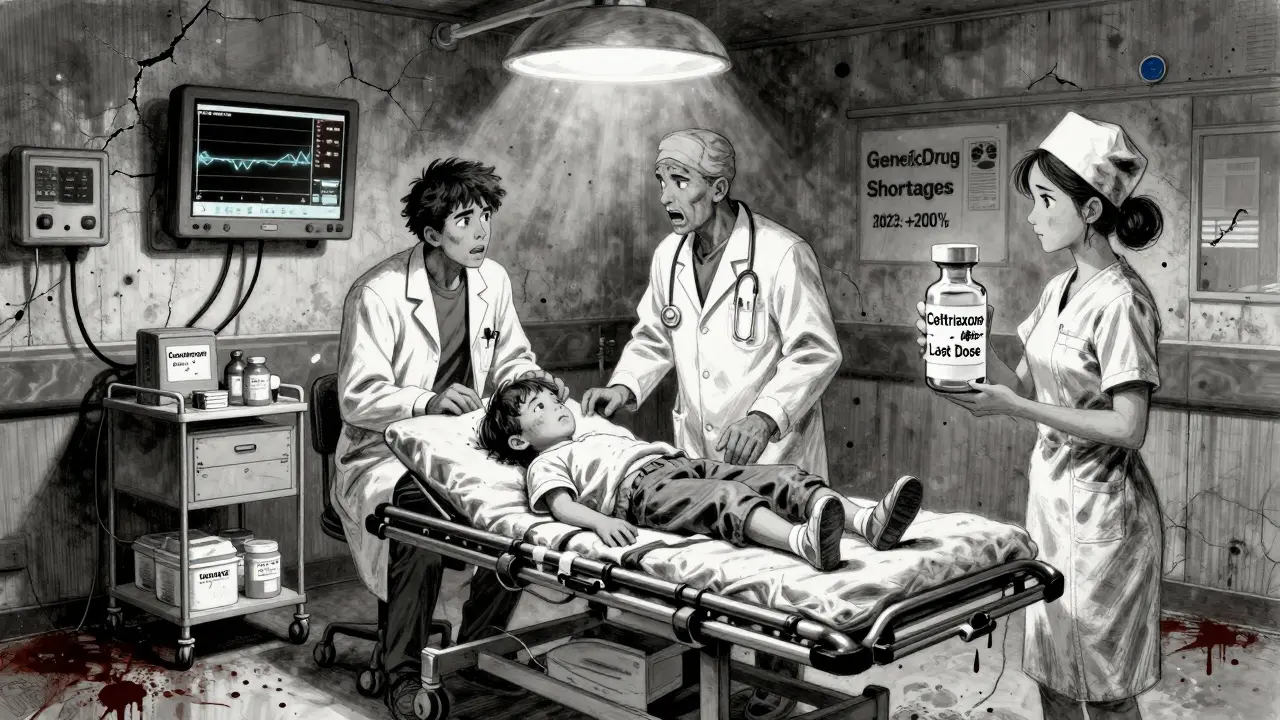

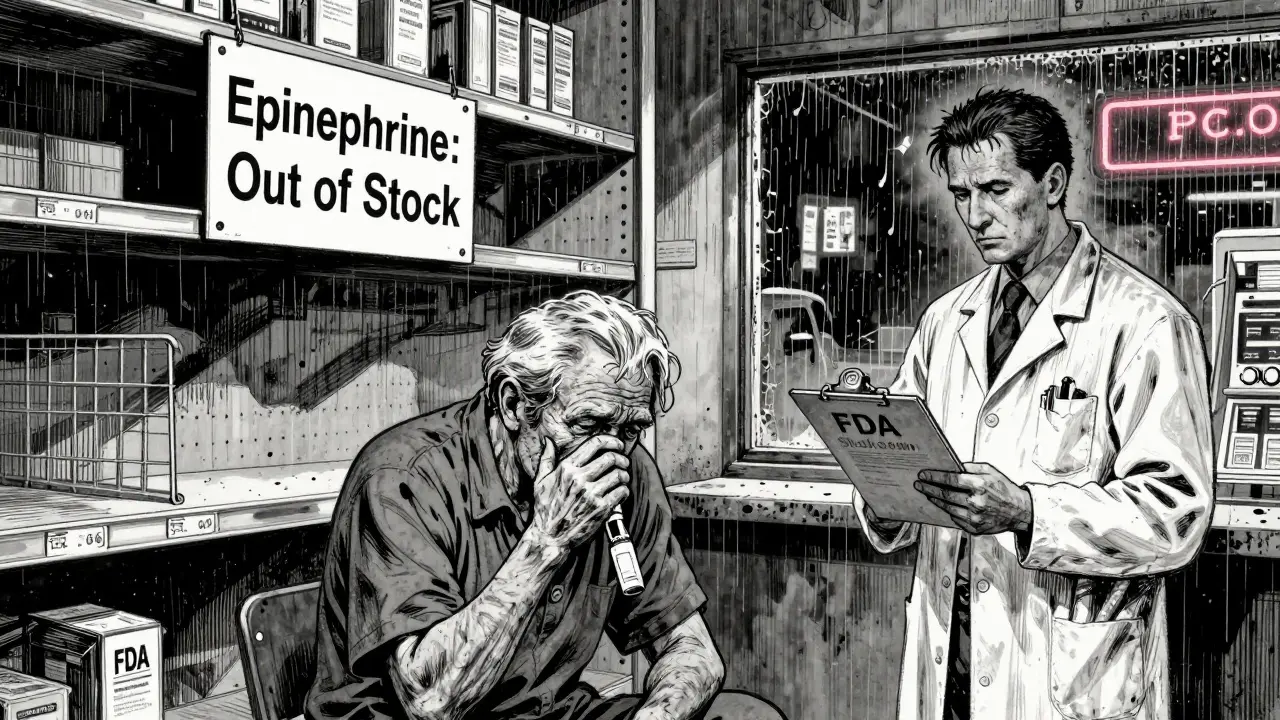

Generic drugs were supposed to be the solution to high drug prices. When a brand-name drug loses its patent, dozens of companies jump in to make copies. Prices drop fast. In the early days of generic competition, a drug that cost $100 might fall to $5, then $2, then 50 cents. That’s great for patients and insurers. But here’s the catch: when prices fall below the cost of making the drug, manufacturers quit. The U.S. Department of Health and Human Services says 9 out of 10 prescriptions today are for generics. That’s a win - until you realize that for some of those drugs, only one or two factories in the entire world can make them. And if one of them shuts down for a compliance issue, a power outage, or just because it’s no longer profitable, the supply vanishes. Take the case of generic epinephrine. In 2023, a major manufacturer had to shut down its sterile injectable line after an FDA warning letter. Suddenly, hospitals couldn’t get the auto-injectors needed for allergic emergencies. The remaining suppliers couldn’t ramp up fast enough. Patients were forced to use expired devices or pay hundreds of dollars for the brand-name version. This isn’t rare. In 2023 alone, the FDA recorded over 200 drug shortages, nearly half of them for generic injectables. And the pattern is always the same: low price → thin margins → manufacturer exits → shortage.Who Makes These Drugs - and Why It Matters

Most people think of generic drugs as being made in the U.S. But the truth is, more than 80% of the active ingredients and 40% of finished generic drugs sold in the U.S. come from overseas - mostly India and China. These countries have the infrastructure to produce drugs at scale, but they’re also under intense pressure to cut costs. The top five generic manufacturers - Teva, Sandoz, Mylan (now Viatris), Aurobindo, and Sun Pharma - control nearly half of the global market. But even among them, competition is uneven. For common pills like metformin or lisinopril, you might find 15 different brands on the shelf. For sterile injectables like heparin or dopamine? Often just one or two. Why? Because making a pill is easy. Making a sterile injection isn’t. It requires clean rooms, advanced equipment, and months of testing just to get FDA approval. Building a facility costs between $200 million and $500 million. Few companies can afford that unless they’re sure they’ll sell enough to cover it. And with prices so low, many just don’t. The FDA approved 956 generic drug applications in 2023. But that doesn’t mean 956 new drugs hit the market. Many of those were for drugs already made by other companies - meaning more players chasing the same tiny profit margin. The result? No one wins.

The Shortage Spiral

Here’s how a shortage starts:- A drug goes generic. Ten companies enter the market.

- Prices drop 90% in two years.

- Three companies can’t cover their costs. They exit.

- Seven remain - but now they’re making more to fill the gap.

- One of those seven has a quality issue. The FDA shuts them down.

- Suddenly, only three companies are left.

- They can’t produce enough. Shortage.

Who Pays the Price?

You might think, “If the drug is cheap, who cares if there’s a shortage?” But here’s the reality:- When a generic runs out, patients get the brand-name version - which can cost 10 to 100 times more.

- Insurers may refuse to cover the brand, forcing patients to pay out of pocket.

- Some patients skip doses or split pills to make it last - dangerous with medications like blood thinners or seizure drugs.

- Emergency rooms see more patients with preventable complications because they couldn’t get their daily meds.

The Fix Isn’t More Competition - It’s Smarter Competition

The European Medicines Agency says the sweet spot for essential medicines is 4 to 6 manufacturers. That’s enough to keep prices low, but enough to ensure backup if one company fails. Right now, only 65% of essential generic drugs meet that standard. The rest? One or two suppliers. That’s not competition - that’s a single point of failure. Solutions are possible, but they require policy changes:- Strategic stockpiles: The government should maintain emergency reserves of critical generics - like epinephrine, insulin, and antibiotics - just like it does for vaccines.

- Price floors: For essential drugs with only one or two suppliers, set a minimum price that covers production costs. Not to raise prices - to prevent collapse.

- Manufacturing incentives: Tax credits or grants for companies that build U.S.-based sterile injectable facilities. Right now, it’s cheaper to outsource - even if it’s riskier.

- Fast-track approvals: If a company has a proven track record of quality, let them enter the market faster for high-risk generics.

What You Can Do

You can’t fix the system overnight. But you can protect yourself:- Ask your pharmacist if your generic drug has had recent shortages. If it has, ask about alternatives.

- Keep a 30-day supply of critical medications on hand - especially if you’re on a drug with a history of shortages.

- Sign up for FDA drug shortage alerts. They’re free and updated weekly.

- If your drug is unavailable, talk to your doctor about switching to a different generic brand - not necessarily the brand-name version.

Why do generic drug shortages keep happening?

Shortages happen because prices for generic drugs have dropped so low that many manufacturers can’t cover the cost of production - especially for complex drugs like sterile injections. When one company quits due to low profits or a regulatory shutdown, the remaining suppliers can’t always make enough to meet demand. This creates a domino effect, especially when only one or two companies make a particular drug.

Are generic drugs less safe than brand-name drugs?

No. Generic drugs must meet the same FDA standards for safety, strength, and effectiveness as brand-name drugs. The only differences are in inactive ingredients, shape, color, or packaging - none of which affect how the drug works. The problem isn’t safety - it’s supply.

Which generic drugs are most likely to be in short supply?

Sterile injectables like epinephrine, dopamine, and heparin are most at risk, along with older antibiotics (like ampicillin), chemotherapy drugs, and some cardiovascular medications. These are often low-cost, high-volume drugs with thin profit margins and complex manufacturing requirements. The FDA’s shortage list updates weekly and shows these categories consistently.

Can the U.S. make more generic drugs domestically?

Yes - but it’s expensive. Building a single sterile injectable facility costs $200-500 million and takes 18-24 months to get approved. Most companies avoid this because overseas manufacturing is cheaper. To change this, the U.S. would need government incentives like tax breaks, grants, or guaranteed minimum purchase agreements for critical drugs.

Will the Inflation Reduction Act make drug shortages worse?

It could. The law allows Medicare to negotiate prices for some drugs starting in 2026. For generics already priced near the cost of production, further price cuts could force manufacturers to stop making them. Without safeguards like price floors or production subsidies, the result may be more shortages, not fewer.

How can I find out if my medication is in short supply?

Check the FDA’s Drug Shortages website, which is updated weekly and lists all current shortages with reasons and expected resolution dates. You can also ask your pharmacist - they’re required to track this information. Some pharmacies even send alerts if your prescription is at risk.

Betty Bomber

January 24, 2026 AT 22:19Been there. Got the prescription for amoxicillin last month. Walked into CVS, no stock. Had to drive 20 miles. They didn’t even apologize. Just shrugged. This isn’t healthcare - it’s a lottery.

George Rahn

January 26, 2026 AT 02:13Let me be blunt: this is the inevitable fruit of neoliberal decay. We outsourced our pharmaceutical sovereignty to sweatshops in Hyderabad and Shanghai because we fetishized marginal cost reduction over national security. The FDA is a paper tiger. The supply chain is a single-threaded spaghetti bowl. And now, when a child needs epinephrine and the only plant in Bangladesh shuts down for a power outage - we weep over spilled insulin. Sovereignty isn’t a buzzword. It’s a lifeline.

Ashley Karanja

January 26, 2026 AT 06:10I’ve spent years in hospital pharmacy operations, and honestly? This isn’t just about profit margins - it’s about systemic fragility. We’re treating life-saving meds like commodities, not public goods. The math is brutal: $0.03 per tablet? That’s not capitalism - that’s a Ponzi scheme built on human desperation. And when you have only one facility in the entire world making a drug, you’re not competing - you’re gambling with lives. We need to stop pretending ‘market efficiency’ is synonymous with ‘public safety.’ We need strategic reserves, we need guaranteed volume contracts, and we need to stop pretending that ‘low price’ = ‘good outcome.’ The patient isn’t a line item.

Aishah Bango

January 27, 2026 AT 17:12People keep saying ‘more competition’ like it’s magic. But if you’re making $0.03 per pill and your rent is $120k/month, you don’t need competition - you need mercy. This isn’t about greed. It’s about the system rewarding exploitation and punishing care. And now we’re surprised when people die because a factory in India had a bad audit? We built this. We chose this. We’re not victims. We’re accomplices.

Uche Okoro

January 29, 2026 AT 16:06Let’s not sugarcoat this: the entire generic drug ecosystem is a structural fraud. The FDA approves 956 applications annually - but 80% of APIs originate from jurisdictions with zero transparency, zero accountability, and zero ethical oversight. The illusion of choice is a weapon. You think you’re saving money? You’re just funding a global oligopoly that operates on bribery, substandard facilities, and regulatory arbitrage. The real crisis isn’t shortage - it’s moral bankruptcy.

Geoff Miskinis

January 30, 2026 AT 20:36Statistically, the concentration of generic injectable manufacturing is more oligopolistic than the telecom industry. Four firms control 47% of the market. The notion of ‘competition’ here is performative. It’s a shell game: regulators celebrate new approvals, while actual production capacity stagnates. The solution isn’t price controls - it’s capacity guarantees. Fund infrastructure like you fund highways. This isn’t healthcare economics. It’s national defense.

Ryan W

February 1, 2026 AT 03:05Y’all act like this is new. We’ve been warned since 2012. The FDA’s own reports show a steady decline in domestic sterile manufacturing since 2005. But we kept outsourcing because it was cheaper. Now we’re mad when the system breaks? Wake up. This isn’t a bug - it’s a feature of deregulated capitalism. The fix? Bring it home. Tax the hell out of imports. Subsidize U.S. plants. Stop pretending we can outsource survival.

Allie Lehto

February 2, 2026 AT 06:47i just found out my mom’s blood thinner is on shortage again 😭 she’s 72 and has to drive 45 mins to get a different brand and the pharmacy didn’t even tell her until she showed up. i’m so tired of this. we’re not talking about vitamins here - we’re talking about people dying because someone didn’t want to spend $2 more per pill. why is this so hard??

Nicholas Miter

February 3, 2026 AT 16:28For anyone saying ‘just buy brand-name’ - that’s not a solution. That’s a luxury. I work with uninsured families. When a $0.50 generic becomes a $120 brand-name drug, they skip doses. They ration. They die. We don’t need more theory. We need policy that says: some drugs are too vital to be subject to market whims. Let’s treat them like fire hydrants - not stocks.

Suresh Kumar Govindan

February 5, 2026 AT 02:40It is a profound irony that the very mechanism designed to democratize access - generic competition - has become the instrument of its own destruction. The market, left to its own devices, optimizes for marginal utility, not systemic resilience. The tragedy lies not in the absence of choice, but in the illusion of it. One must ask: if the price of a drug is less than the cost of its transportation, who is truly paying the price?

Karen Droege

February 5, 2026 AT 09:19Look - I get it. We want cheap drugs. But here’s the brutal truth: you can’t have cheap AND reliable AND global. Pick two. Right now we picked cheap and global - and we’re getting neither. We need a Marshall Plan for generic manufacturing. Tax breaks for U.S. sterile production. Mandatory stockpiles. Guaranteed minimum orders for critical meds. This isn’t socialism - it’s sanity. And if you think this is just about money, you haven’t held a child’s hand while they wait for an EpiPen that doesn’t exist.

Shweta Deshpande

February 6, 2026 AT 04:36My grandma’s heart med ran out last winter. She was so scared she started cutting pills in half - and then she got dizzy and fell. We had to rush her to the ER. The pharmacist said, ‘Sorry, the next shipment’s in 3 weeks.’ I cried in the parking lot. We’re not asking for luxury. We’re asking to not die because a factory in India couldn’t afford the new air filters. Please. Let’s fix this.

Rakesh Kakkad

February 8, 2026 AT 03:46The structural vulnerability of the generic drug supply chain is a direct consequence of the commodification of essential medicines. The absence of price floors for critical injectables represents a market failure of existential magnitude. Regulatory capture by multinational conglomerates has rendered the FDA’s approval process a procedural theater, devoid of substantive risk mitigation. The solution necessitates a paradigmatic shift from price-driven procurement to resilience-based procurement architecture.

Faisal Mohamed

February 9, 2026 AT 08:31It’s funny - we celebrate free markets until they kill someone. Then we panic. But we never ask: why are we letting a $0.03 pill dictate whether a diabetic lives or dies? This isn’t capitalism. It’s a death sentence disguised as economics. We need to stop pretending the market is neutral. It’s not. It’s rigged. And the winners? They’re not the patients. They’re the shareholders.

Josh josh

February 10, 2026 AT 12:37my pharmacist just told me theyre out of metformin again. again. like every 3 months. i just want my pills. why is this so hard. why cant we just make them here. why dont we just pay a little more. why dont we just care.